BU manager: Mr. Marco Manueddu

senior Sales engineer: Mr. Daniele Sagone

ROPEX Industrie-Elektronik GmbH

ROPEX IS A LEADER IN THE FIELD OF IMPULSE SEALING SYSTEMS FOR PLASTIC FILMS AND HAS A SOLID INTERNATIONAL REPUTATION BUILT IN OVER FORTY YEARS OF ACTIVITY

Founded in 1975, it has steadily developed to become the world’s leading player in the target market. ROPEX’s team of specialists creates solutions to meet the needs of their partners with a mix of knowledge, creativity and practical insight.

Over time, the fields of application of ROPEX technology have expanded and include, just to name a few:

1. medical and pharmaceutical thanks to the possibility of carrying out the validation of the Temperature and process

2. Mattress covers, polyurethane blocks or other materials, even large dimensions

3. retail, HORECA, pet and livestock food packaging (bags, sacks, trays)

4. Bags for plastics, concrete powder, etc.

5. Packaging of household appliances

6. Pallet hooding

7. Welding of mosquito nets or plastic sheets

8. Battery Construction

Sealing is the Achilles’ heel of thermoplastic packaging: without proper control of temperatures and of the process in general, the film may not be perfectly sealed, does not meet aesthetical and quality requirements, or it is difficult to manage in the process and handling. ROPEX impulse sealing welding systems produces reliable seams thanks to highly dynamic temperature control that is extremely fast and accurate as well.

Other advantages are that the first sealing of the cycle at the start of the machine/line is already the one needed, reduction of waste and greater environmental compatibility of the process. The ROPEX solutions are applicable not only in the case of linear sealings, but also in the case of need of 2D and 3D contours such as special bags, euroholes, nozzles/spouts.

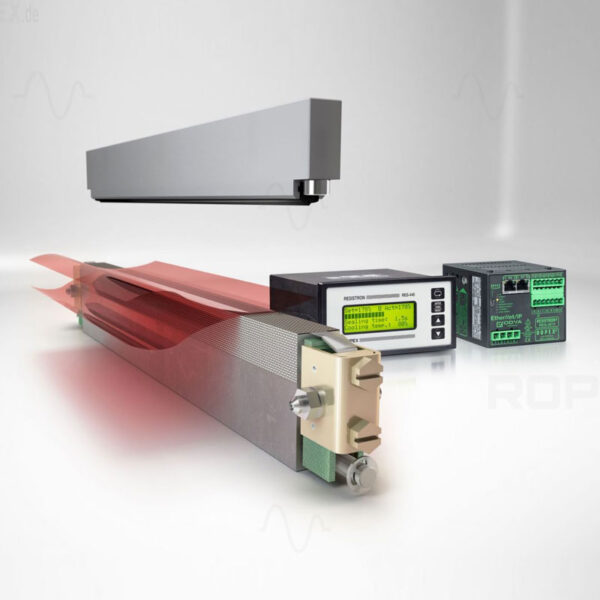

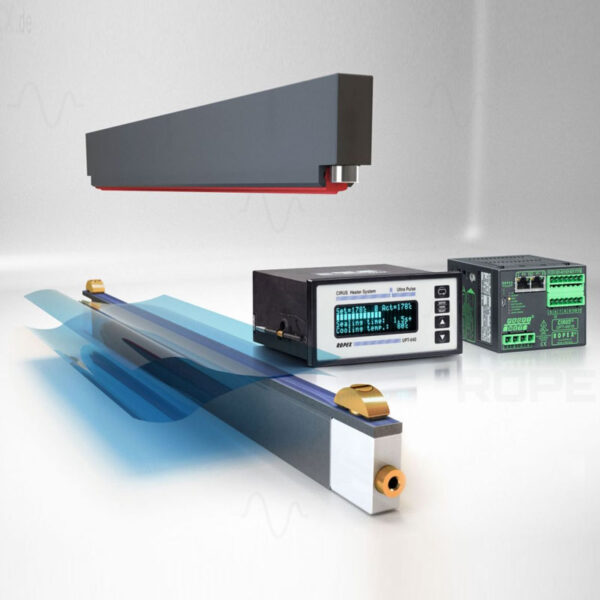

Technology trends such as IoT and Industry 4.0 in combination with the cloud computing, are increasing the demand for packaging systems with controllers able to interface, through different protocols, with the company information system. For this reason, ROPEX also offers controllers compatible with PROFIBUS, PROFINET, Ethernet/IP, EtherCAT, CAN-Bus/CANopen. These solutions also implement the diagnostic capabilities of ROPEX controllers and how to manage the process.

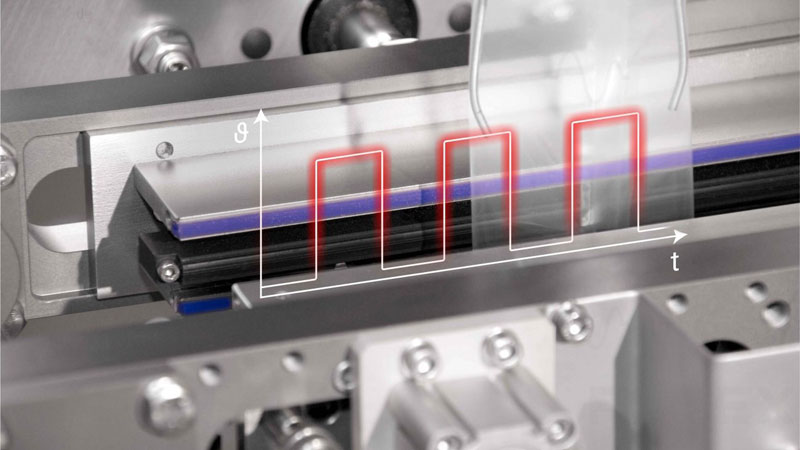

WHAT IS THE IMPULSE SEALING TECHNOLOGY?

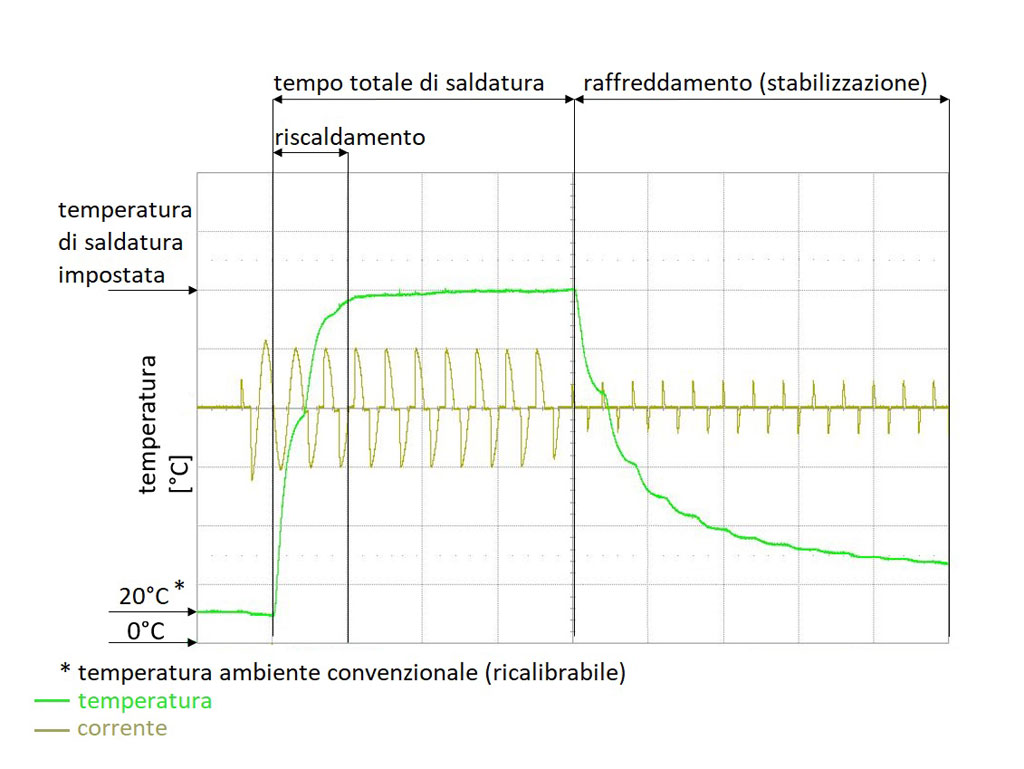

It is often thought that the pulse is temperature, but actually it refers to the Electrical impulses. The controller, depending on the temperature coming from the measurement of current and voltage of the thermoresistance and knowing its TCR (Resistance Temperature Coefficient), decides in a few milliseconds and with a frequency of 50 Hz whether to deliver all the available power or to partialize it. You can then increase the temperature only when needed and very quickly (up to 6000K/s), keep it for as long as necessary in a controlled manner, reduce it quickly once sealling has taken place to stabilize the material.

Unlike older technologies, impulse sealing allows to cool-down the seasm with sealing bars still closed: this makes the process faster and with a superior and constant quality of the result from the first machine cycle.