The use of SOS technology in differential applications offers a reliable, long-lasting solution with unbeatable performance and value. SOS differential pressure transmitters from ESI are bidirectional and extremely robust, allowing the monitoring of applications with high line overpressures and transients that are critical or unmanageable by traditional sensor technologies.

The robust build of the pressure transmitter does not affect its excellent precision, accuracy and stability over time.

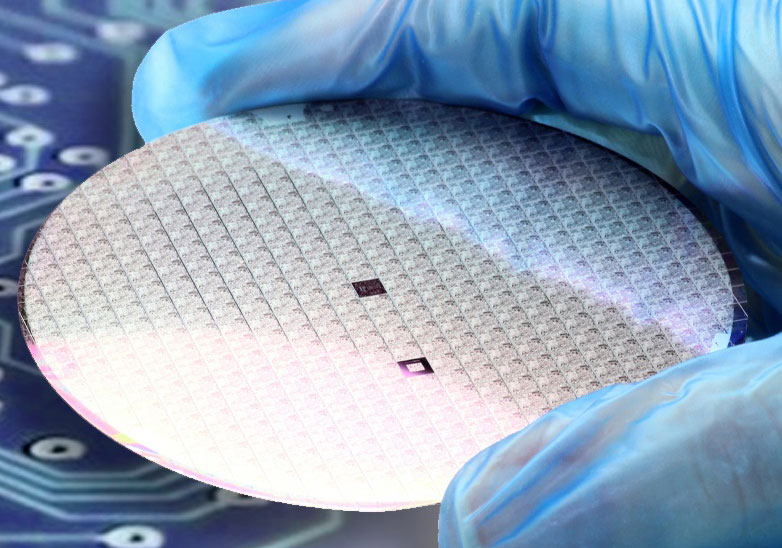

A very practical experiment in 1963 at North American Aviation (now Boeing) led to the discovery of SOS. A sapphire crystal was polished into a spherical shape and immersed in a gas containing silicon. A spherical surface will expose all of the planes that exist in a crystal system. It was found that silicon grew in certain sites on the sphere, and these were identified as corresponding to the R plane of sapphire.

In the mid 1960’s researchers worked on turning S.O.S into a manufacturable technology. The primary application was for radiation hard circuits, but it soon became apparent that the other benefits of S.O.S could lead to commercial usage.

A further breakthrough was the development of ultra-thin S.O.S films by the California Institute of technology along with Hewlett Packard in 1978. A process called SPER (Solid Phase Epitaxial Re-growth) was developed until the stage where S.O.S could be commercialised for the first time in 1990.

Silicon-on-Sapphire is now the superior pressure sensing technology and is gaining broader acceptance in higher volume applications.

ESI, founded in 1984 and joined the SUCO Group in 2009, started the production of SOS sensors in 1994, optimising processes over time and the production is still in-house.

SOS is one of the most promising pressure-sensing technologies today and is

used extensively by the SUCO Group, of which ESI is a part.