With ATLANTA Service you enter the world of Industry 4.0 with us by introducing the first digital mapping system for your racks. This system allows the racks to be consciously matched to efficiently achieve the linear positioning accuracy required by the application.

All this is made possible thanks to the integration of the production processes, information systems and state-of-the-art quality control systems of the ATLANTA smart factory and the special laser marking of the racks.

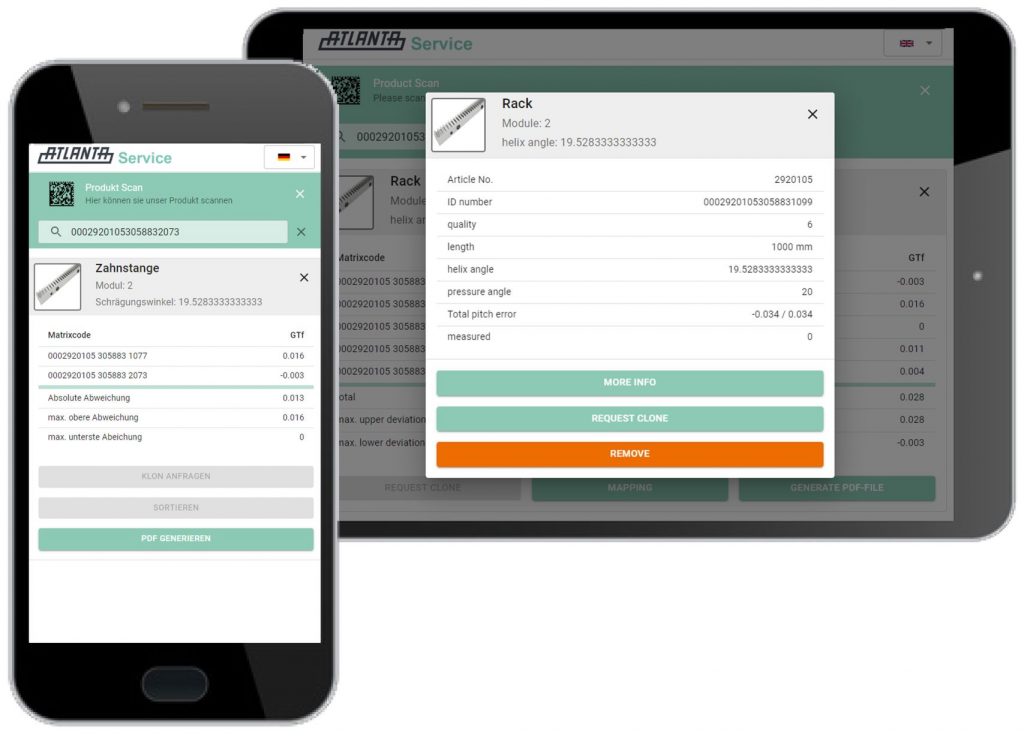

The ATLANTA application includes the unique “Product Scan” tool that allows you to:

- Access the rack data at any time (code, order number, serial, quality, module, length, number of teeth, nominal and measured total pitch error)

- Determine the optimal assembly sequence of a defined number of scanned racks (“mapping” function)

- Filter from a set of available racks those that minimize the total pitch error (“mapping” function)

- Request to ATLANTA the clone of the scanned product (digital twin/clone function)

If only one rack of a line needs to be replaced, it is usually necessary to carry out a new assembly of the row, followed by the subsequent complete alignment and calibration of the entire system.

The ATLANTA-exclusive process includes, as the final step in the construction of the racks, the individual measurement and storage of the data in the database updated in real time. This makes it possible to identify the clone of the rack to be replaced (digital twin) in the ATLANTA warehouse. It is therefore sufficient to replace the individual rack with the clone and proceed to align it with the pre-existing racks, without requiring further operations. The immense advantage in terms of maintenance time and costs is evident.

Thanks to the measurement of each individual rack, ATLANTA is able to select from its stock the most suitable ones for the needs of the application: this allows to be able to create theoretically infinite strokes of length, ensuring that the real positioning error is in accordance with the specification.

ATLANTA has developed its own servo worm gear units and linear actuators with a modular motor coupling system.

The “Motor match”, thanks to the extensive database, allows you to easily check if the selected servo motor can easily fit with the ATLANTA solution and identify any necessary components.

Obviously, the know-how of the ATLANTA technical department will analyze the application, project constraints and specifications on request, providing the overall optimized solution.

Contact us to develop the right solution for you.